Returning Students

You may also like:

Most Recent:

- GMP- Good Manufacturing Processes for food 2010.10.28 Good Manufacturing Processes for food

- HACCP Principle 4 - Establish Monitoring Procedures 2009.09.21 HACCP Principle 4 - Establish Monitoring Procedures

- HACCP Certification Training Home 2009.09.21 HACCP Certification Training Online

Approved Course

Applying HACCP Principles™ For The Food Service Industry has been Reviewed and Accredited by the HACCP Alliance as meeting the required standards for content and training for introductory HACCP.

Bookmarks & Feeds

News:

HACCP Wireless Refrigeration Monitoring System

HACCP Wireless Refrigeration Monitoring System requires no PC or software

Understand HACCP and Improve Food Safety in Your Restaurant

Articles » Understanding HACCP and Improving Restaurant Food Safety

By Gregory Scott McGuire

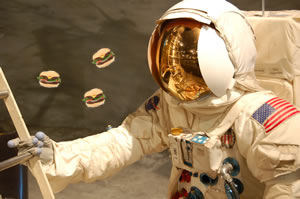

The HACCP, or Hazard Analysis and Critical Control Point, is a set of guidelines and procedures for food safety originally developed by NASA for astronaut food 30 years ago. NASA needed a food safety program with "zero tolerance" to protect astronauts from food borne illnesses while in space. One can imagine the consequences of a bad sandwich in a spacesuit...

Anyway, these guidelines have been adopted by most restaurants to ensure the safety of the food product and ingredients used and prepared in their kitchens.

HACCP is unique because it focuses on analyzing problem points in the production of food and develops ways to address those hazards rather than testing final products for food borne illnesses.

As a restaurateur, you are probably already familiar with HACCP guidelines. This information is meant to be a quick refresher course on all the aspects of an effective HACCP program. Of course, different local health standards in different areas of the country will have their own guidelines for food service, and you should always follow those guidelines over anything said here.

The HACCP system is internationally used and recognized. The principles of a HACCP are:

1) Conduct an analysis of food safety hazards in the preparation and production of food products in a commercial kitchen. The three hazard categories include biological (pathogens like bacteria or viruses), chemical (toxins or poisonous agents), and physical (foreign objects).

2) Identify critical control points for managing these three types of risks. The most common control points in the commercial kitchen include heating, cooling, preparing, and serving food product. Use NSF certified restaurant equipment and restaurant supplies to make sure the tools in your kitchen are designed with food safety in mind.

Also keep in mind the HACCP system is designed to cover all the steps in the process for food, from harvesting to consumption, so even though your restaurant may not become involved until the end of that process, you should still attempt to identify problem points that occur before product ever comes through your door. Make sure you know your food suppliers and their food safety procedures.

3) Establish critical limits for food passing through a critical control point. For instance, cooked food must reach 140 degrees Fahrenheit, etc.

4) Develop a system that monitors critical limits and ensures they are being met. Thermometers are key to making sure food reaches the 140 degree critical limit. Data loggers can monitor temperature fluctuations over time in walk-in refrigerators or freezers. No matter what, the critical limits need to be logged and quantified in order for you to understand if the critical points you addressed in the hazard analysis phase are being met.

5) Have procedures to address problems when critical limits are not met. The whole point of establishing a critical limit at critical points in the food preparation process is to spot potential problems immediately. Once that system functions properly and actually finds a problem, you need to have procedures to address them.

6) Establish an effective documentation system for any HACCP program that records problems and data like time and temperature. Without such documentation, you have no way of identifying problems in your food safety program and documenting for health inspectors the good practices of your HACCP program.

Modern food safety equipment like data loggers can be connected directly into a computer and temperatures automatically loaded into a database. Taking advantage of such technology not only saves you time but makes your safety program more effective.

Controlling the critical food safety points in your restaurant is key to anybody's success in the food service industry. Having an effective HACCP program is good business practice, and will keep your customers safe and the health inspector happy.

Gregory Scott McGuire is a regular contributor to The Back Burner Blog, a resource of restaurant news and trends written by the employees of Tundra Specialties, a company specializing in restaurant equipment, supplies, and equipment parts